Electronic applications require reliability, purity and precision. Bakelite® and Durite™ phenolic resins are used to produce high-quality electrical and electronic components that meet these stringent requirements while making manufacturing easier.

Bakelite® cresol novolac resins offer advantages for printing plate production. Benefits of ultra-high purity Bakelite cresol novolacs include:

Applications for Bakelite® cresol novolacs include:

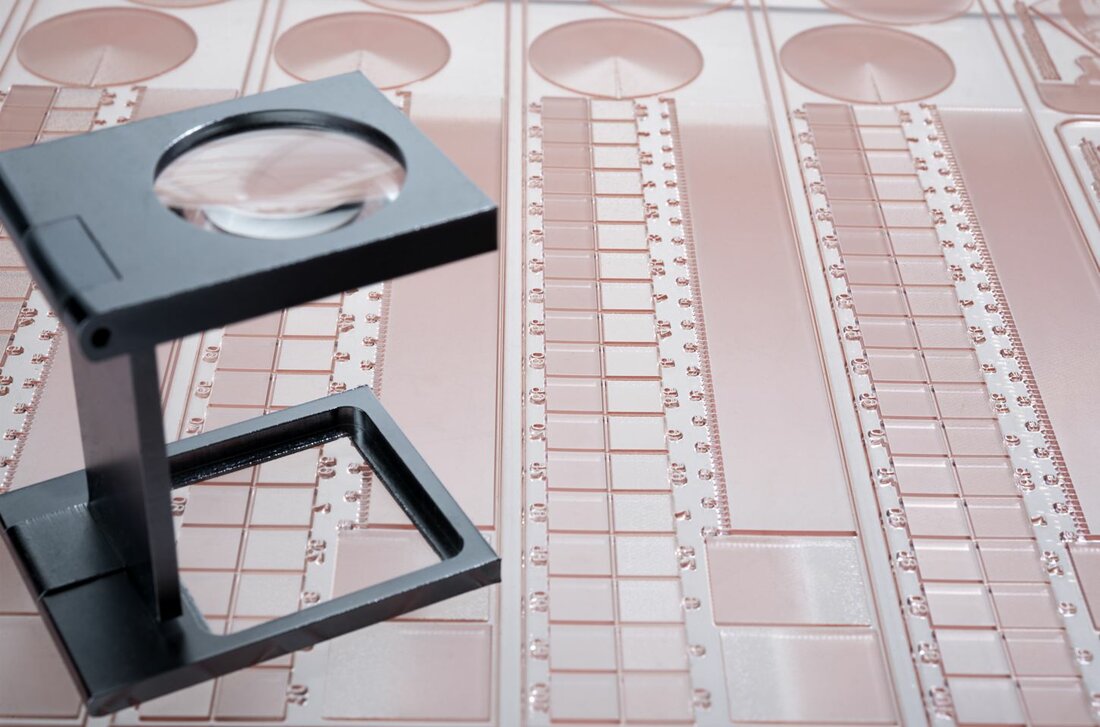

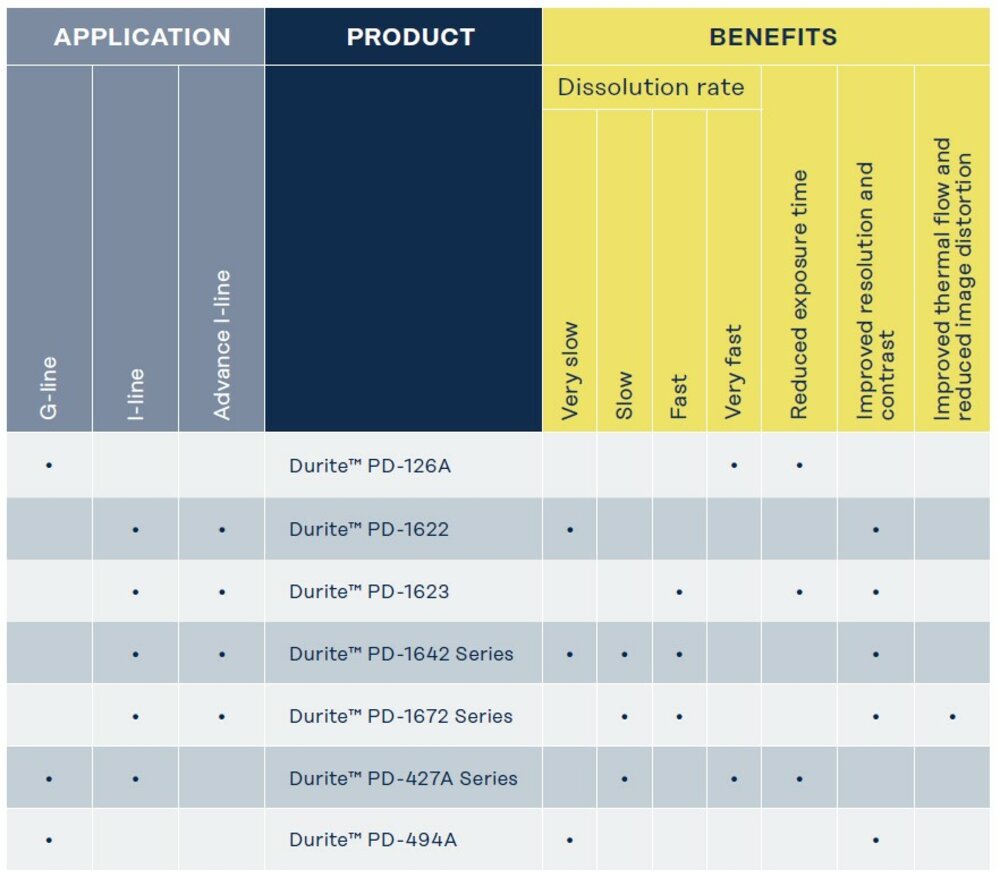

Bakelite® and Durite™ phenolic/cresylic resins are ideal for photoresist formulations used to manufacture components for the semiconductor industry as well as LED production. These resins are specifically designed for g-line, i-line and advanced i-line lithography.

Optimized monomer ratios and controlled processing enable Bakelite to produce resins featuring a range of molecular weights and dissolution rates. Benefits of our resins include:

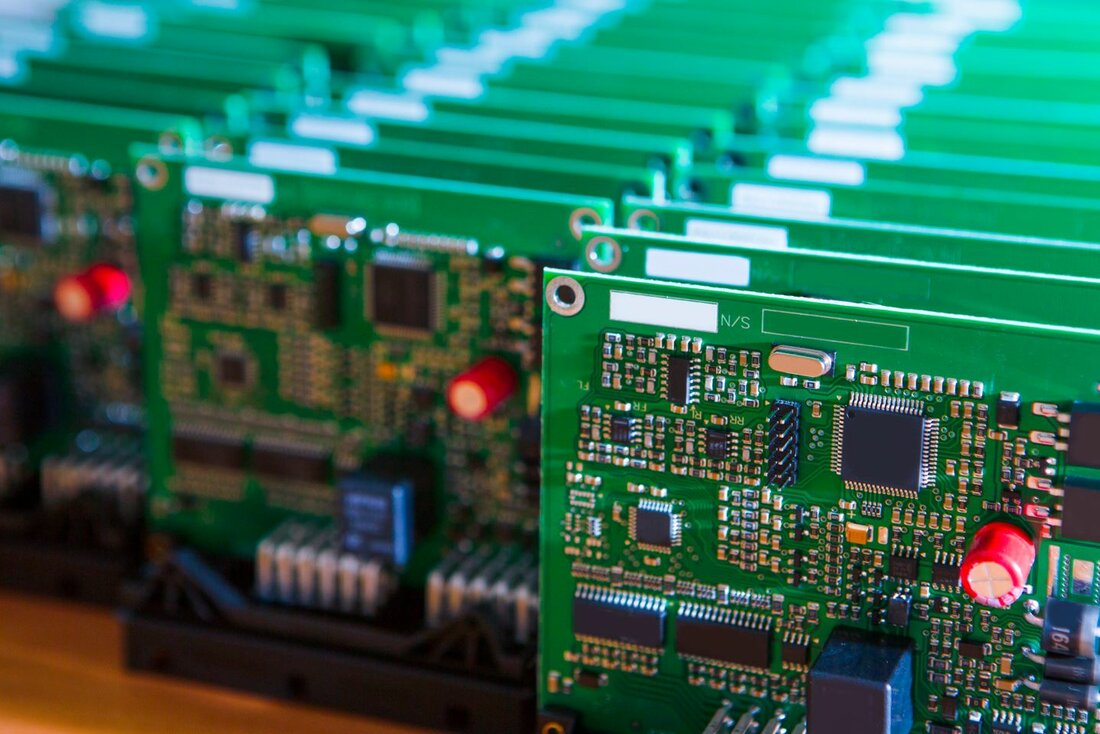

Heat and moisture resistance are crucial for printed circuit boards (PCBs). Bakelite® and Durite™ high purity resins are used for chip encapsulation, as underfill adhesives, and in the impregnation of copper clad laminates (CCL) for PCBs. These resins provide:

To meet your specific application requirements and to ease manufacturing, our technical team will tailor resin attributes, such as:

You want to join our story as a customer or as a talent? We are looking forward to hearing about your ideas or help you if you would like to know more about a product or technology.

North America, South America, Australia

Your contact for Phenolic and Amino Resins.