Bakelite® Molding Compounds for Commutators

For many decades, Bakelite® molding compounds have been used with great success in manufacturing commutators and slip ring elements. The experience gained over this period and trust-based teamwork with processors and final users of Bakelite® molding compounds have contributed to the unbroken continued development in this field.

The increasing capacities of electric motors coupled with unchanged or even more compact physical dimensions lead to greater thermal and mechanical stresses on the insulating molding compound int the commutator. Moreover, such motors are expected to offer even lengthier service lives despite the increased rotational speeds and more compact physical dimensions.

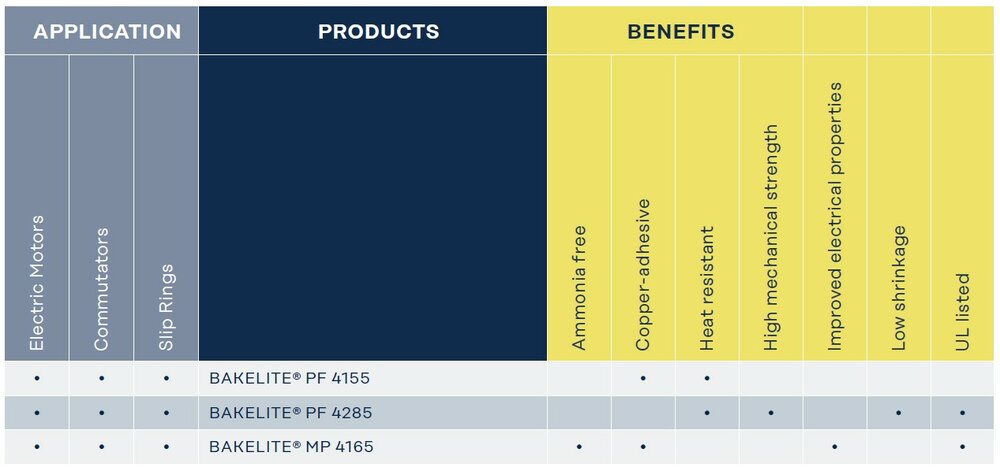

The Bakelite product line – offering melamine-phenol and phenolic molding compounds – is in line with these strict requirements and offers a wide range of products for all common types of commutators.

For automotive, household and industrial applications Bakelite® thermoset molding compounds are utilized when there must be a combination of:

- Achieve multiple grades with single grade of asphalt.

- Adjust stored/aged asphalt to desired spec.

- Achieve PG improvement with less modifier.

- Achieve higher performance with lower-cost asphalt.

- Add in-line for ease of incorporation.

- Attain low PG asphalts for some blend stocks.

- Utilize a high flash point and low toxicity modifier.

- Limit effects on mass loss.

- Improve compatibility of Styrene-butadiene-styrene (SBS) polymer in Polymer Modified Asphalt Cement (PMAC).