Bakelite® Phenolic Resins for Rubber Compounding

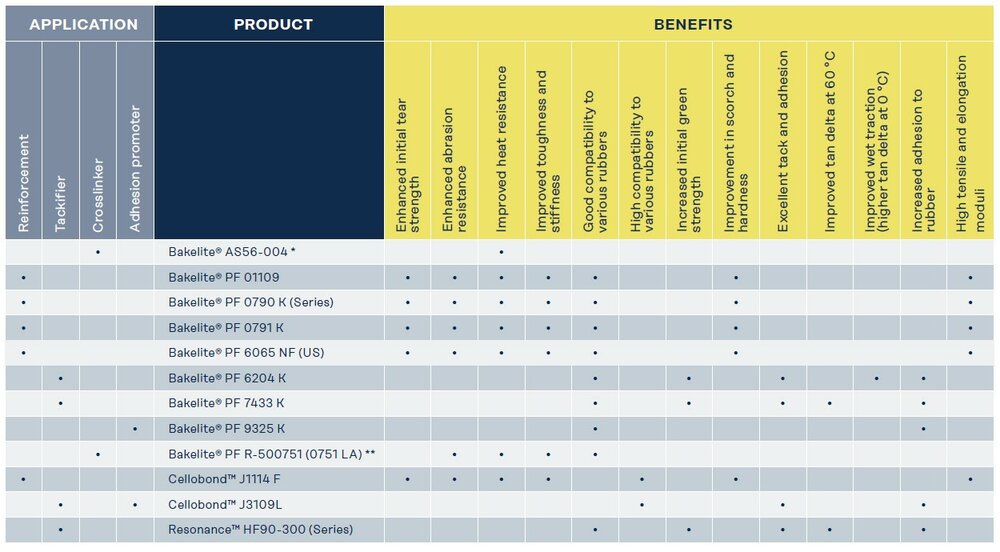

Bakelite’s family of resins for rubber compounding includes reinforcing resins, tackifiers, vulcanizing agents and adhesion promoters.

Tackifier resin acts as a processing aid in unvulcanized rubber mixtures. reinforcing resins. For vulcanized rubber products, our resins improve:

- Processability

- Hardness

- Tensile strength

- Abrasion resistance

- Temperature and chemical resistance

- Outstanding adhesion, particularly of tire cord to the rubber in steel belted radials tires.