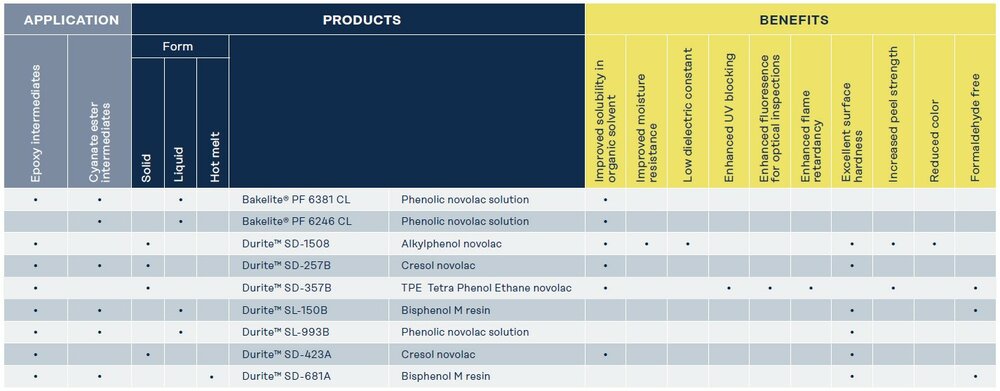

Bakelite® Intermediates for Epoxy / Cyanate Ester

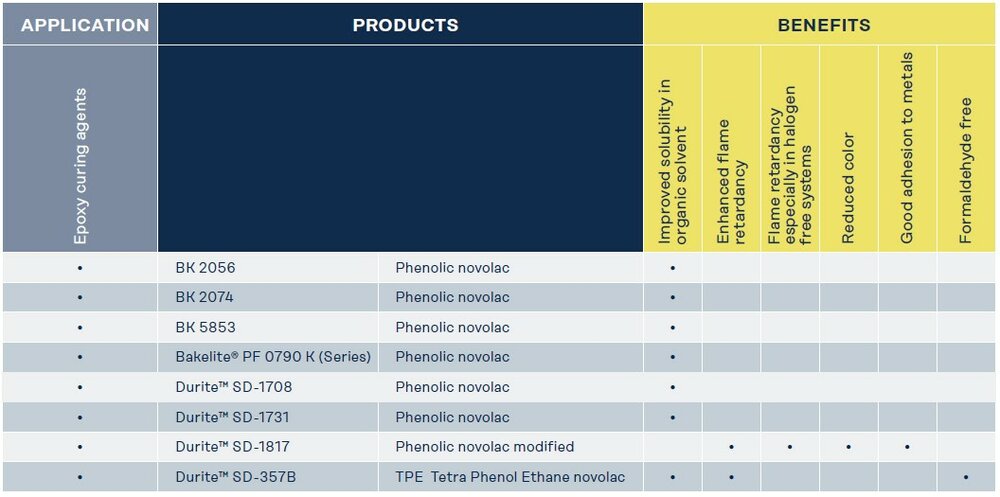

EPOXY AND CYANATE ESTER INTERMEDIATES / EPOXY CURING AGENTS

Producers of multifunctional epoxy resins and cyanate esters can draw from a range of Bakelite® and Durite™ phenolic resins to develop their products, including:

- Ultra-low molecular weight phenolic novolacs

- Dicyclopentadiene (DCPD) phenol adducts

- Diisopropenylbenzene-phenol adducts

- Phenol-glyoxal polymers

- Cresol novolacs and bisphenol-A intermediates

- Modified novolacs

- Bis-M intermediates

These novolacs are produced within various specific molecular weight ranges to suit our customers’ needs. They are easily glycidated, contain low free monomer (phenol and cresol) concentrations, and are designed for epoxy chain-extending reactions. Acting as crosslinkers, our products perform as hardeners for epoxy formulations. Common applications for the epoxidized resins are printed circuit boards, heat-resistant composites and corrosion-resistant coatings.

Cyanate esters based on our chemical intermediates are well-suited for applications such as high temperature composites and adhesives that require high Tg ( 300°C or higher). Phenolic resins enable important characteristics essential for electrical- and electronic-grade adhesives such as:

- Low curing temperature

- Excellent dielectric constant

- Low moisture absorption

- Corrosion resistance

- UV blocking/Fluorescence