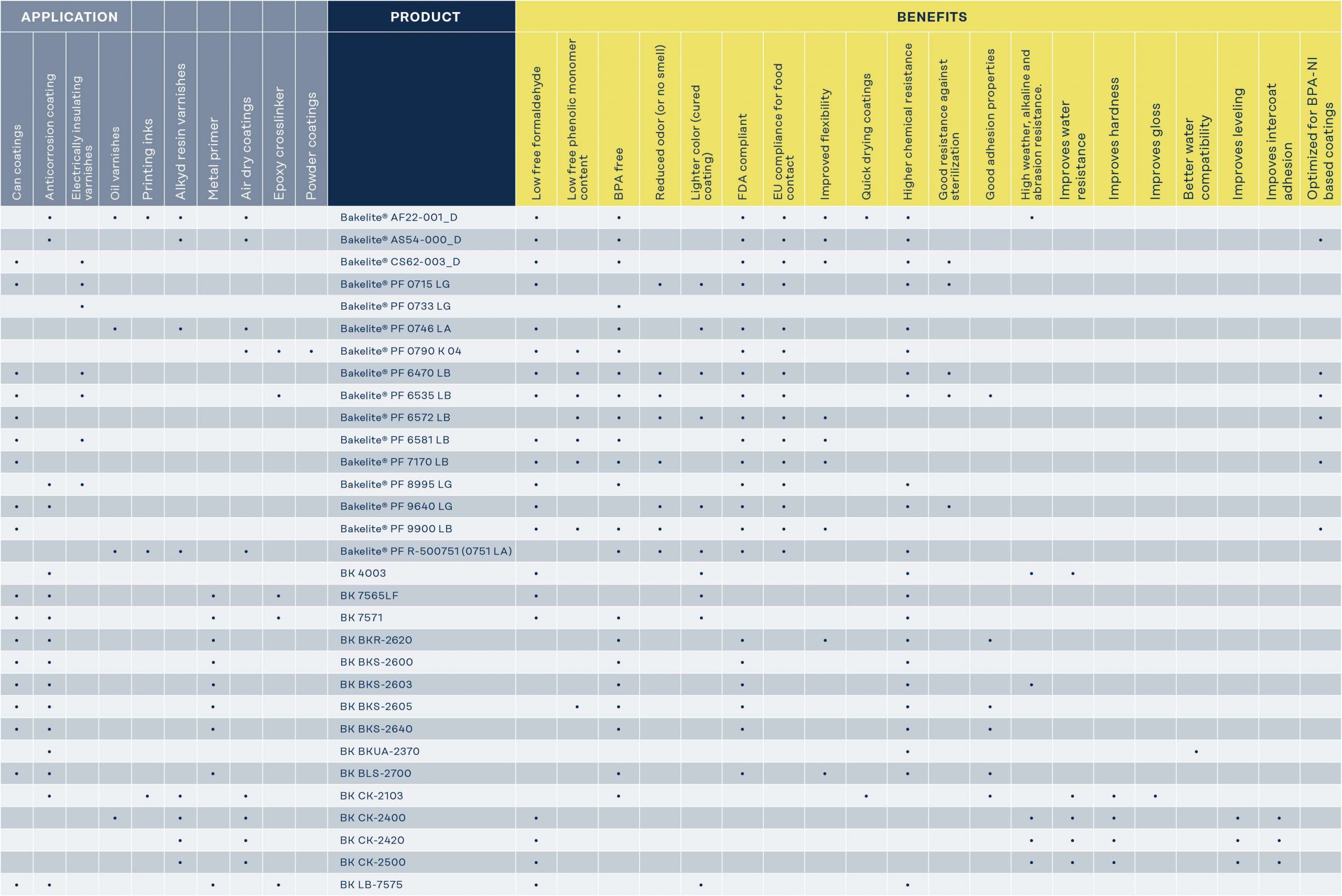

Bakelite® Resins for Protective Coatings and Inks

Phenolic resins were the first synthetic resins used in the coating industry. Bakelite® resins provide formulation latitude as they are compatible with many types of polymers including epoxies, polyesters, alkyd, vinyl and acrylics in a variety of solvents including alcohols, glycol ethers and ketones. Products are also dilutable in aromatics. They serve as excellent crosslinking agents for other polymers to form coatings with good adhesion and chemical resistance properties. Crosslinking takes place either under high temperature (~180°C) or at lower temperatures via acid catalysts.

Phenolic coatings offer consistent, high quality corrosion protection, chemical resistance, electrical resistivity, and excellent adhesion to metal. Our resins are used to produce chemically-resistant food contact and anti-corrosion coatings.

Because of their properties, Bakelite phenolic resins are used in abrasion-resistant and thermal barrier films as well.

Modified phenolic resins can be made oil soluble and act as good binders for printing inks.

We know that every application and formulation is different. Our knowledge of these resins provides us the foundation to select or develop the optimal product that will meet your specific manufacturing process or performance needs.