Bakelite® Resins for Friction Applications

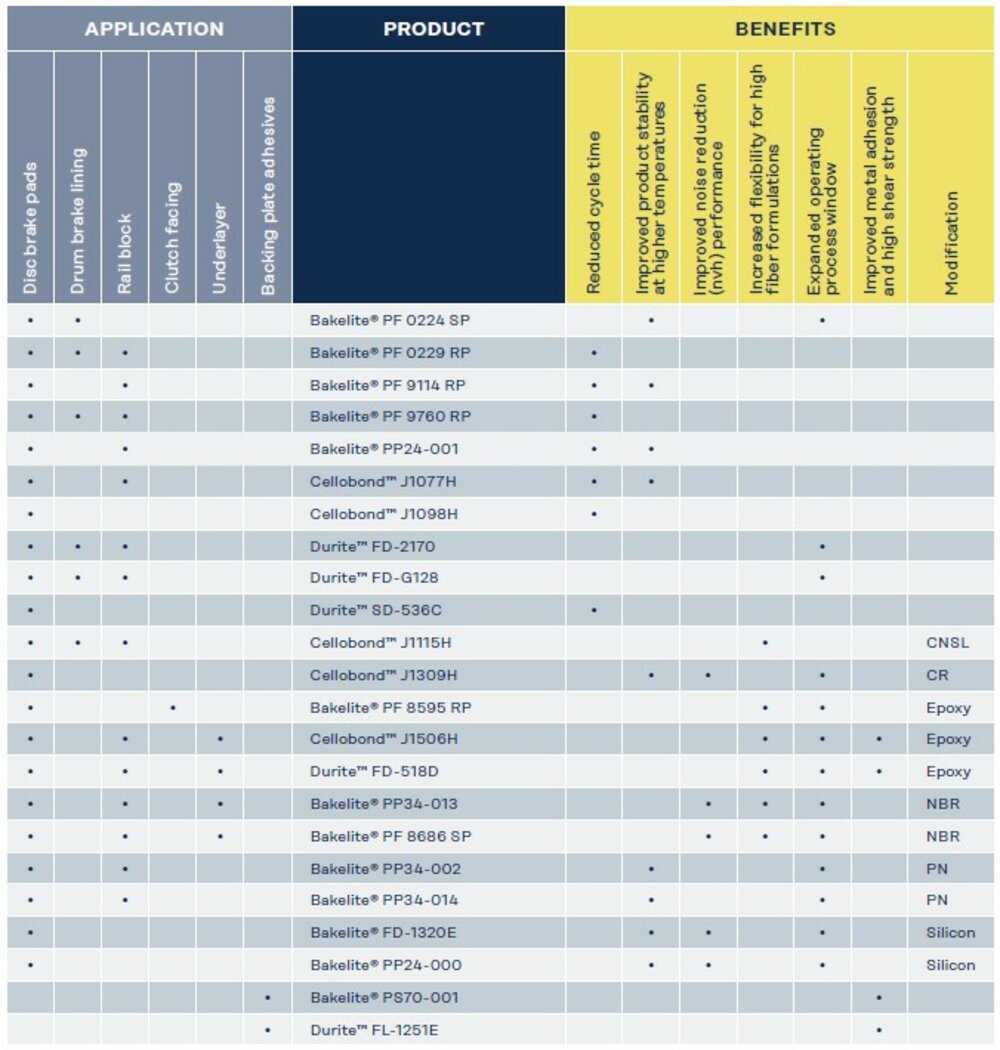

Bakelite has developed a comprehensive portfolio of high-performance resins with high heat-resistant and desired NVH (Noise, Vibration and Harshness) properties for the friction market that meet the specific and evolving needs of customers in the automotive, rail, aerospace and industrial equipment segments. We offer a wide selection of unmodified and modified resins, in both liquid and powder form. These are compatible with a variety of friction formulations and manufacturing processes including compression molding (cold, warm and hot), impregnation and saturation. Our resins help boost productivity through shorter cycle times in applications such a disc brake pads, brake shoes, brake blocks, drum brake linings and clutch facings. Bakelite® phenolic resin systems can be tailored to meet the strict specifications and certifications for rail and mass transit brake system components.