Bakelite resins are an essential part of manufacturing High Pressure Laminates (HPL) which are used in making kitchen counters, flooring, cabinets, tabletops, and more.

Bakelite resins are an essential part of manufacturing High Pressure Laminates (HPL) which are used in making kitchen counters, flooring, cabinets, tabletops, and more.

History of HPL

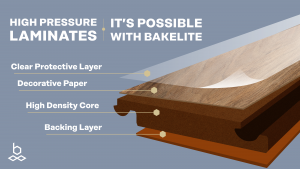

HPLs first appeared over 100 years ago as electrical insulation. Soon they became popular in mid-century kitchens. The core of every HPL product includes layers of phenolic resin and saturated kraft paper. The top layer is decorative paper saturated with clear melamine resin, allowing the color of the paper to be part of the final HPL product.

Today, Bakelite supplies phenolic and melamine resins for HPL production. These resins are manufactured at Bakelite sites in North America and Europe.

How it Works

To make High Pressure Laminates, kraft paper is treated in a saturator that covers both sides with phenolic resin. The paper is dried in a warm oven, where the resin becomes “b-staged.” It’s not cured yet, but the resin is fully incorporated into the paper. The same process applies to melamine resin, but with unique patterned paper. Layers of phenolic kraft paper are stacked with a top layer of decorative melamine paper and a special die that imprints texture onto the melamine surface. The final thickness of composed sheets ranges from 1/10” to over 1” thick.

The Bakelite Difference

Modern High Pressure Laminates products are more advanced than those from the 1940s and 50s. Today’s resins:

- Resist warping and blistering from heat exposure

- Allow for straight or curved edges

- Created with unique textures, patterns, and shapes

Just one of our resin customers makes more than 20,000 unique products.

Next time you visit a home store, watch a home design show, or start a home renovation, remember Bakelite’s role in creating these end use products.